Inked and Embroidered: Choosing the Right Ink for Your Job

There are countless ways exist to express love. Some people use words, while others use gestures. But what about those who prefer to express their love through art? That's where embroidery comes in.

As the famous quote goes, "Love is a canvas furnished by Nature and embroidered by imagination."

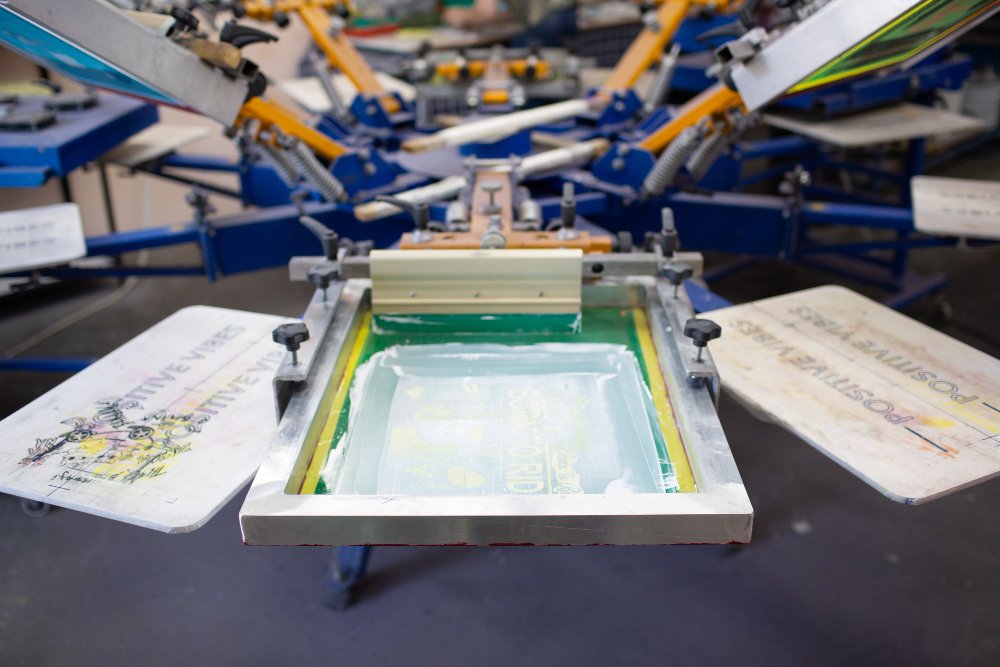

And what better way to bring that imagination to life than through screen printing and embroidery? These two techniques offer endless possibilities for creating beautiful and unique designs that can be worn or displayed.

Water-Based Inks: The Eco-Friendly Option

Water-based ink is a type of ink that uses water as its primary solvent. It is eco-friendly, non-toxic, and has a softer feel than plastisol ink. It's ideal for printing on light-colored fabrics and screen printing, making it a versatile choice.

Why Water-Based Inks are the Way to Go for Screen Printing

Water-based inks are famous for screen printing due to their eco-friendly properties. They are free of harmful chemicals, making them safe for the environment and the people using them. Water-based inks, being breathable, do not affect the feel or texture of the fabric on which they are printed. That makes them an excellent choice for printing on soft, delicate fabrics like cotton.

Another advantage of water-based inks is that they produce a more detailed print. They are thinner and more fluid than plastisol inks, which allows them to penetrate the fabric more deeply. That results in a sharper, more defined print that is less likely to crack or fade over time. Additionally, water-based inks are more versatile than plastisol inks. You can mix them to create custom colors, and they are suitable for printing on various materials, including paper, cardboard, and plastic.

Plastisol-Based Inks: The Heavy-Duty Choice

Plastisol-based ink is a type of ink that uses PVC resin as its primary ingredient. It is a thicker, more viscous ink than water-based ink and is known for its ability to produce bright, bold colors. Plastisol-based ink is ideal for the screen printing process on dark-colored fabrics, providing better opacity and coverage than water-based ink.

The Advantages of Plastisol-Based Ink

One of the main advantages of plastisol-based ink is its durability. It forms a strong bond with the fabric, resulting in a long-lasting print resistant to cracking and fading. Plastisol ink is also easier to work with than water-based ink. Its thicker consistency makes it easier to control and reduces the risk of ink bleeding or spreading on the fabric.

Another advantage of plastisol ink is that it can produce a broader range of colors than water-based ink. Plastisol inks can create custom colors and produce a brighter, more vibrant print on dark fabrics. That makes them ideal for printing on materials like polyester or nylon, which are challenging to print with water-based inks.

Which Ink is Better for Your Job: Water-Based or Plastisol-Based?

Deciding which type of ink is best for your job depends on several factors. If you are looking for an eco-friendly option that produces a softer print and is suitable for printing on delicate fabrics like cotton or embroidery in Norman, OK, water-based ink is the way to go. However, plastisol-based ink is the better choice if you are printing on dark-colored fabrics or need a more durable print that will withstand multiple washing items.

Let's Bring Your Ideas to Life - Contact Us Now!

If you need high-quality screen printing in OKC, look no further than University Silkscreen. We use both water-based and plastisol-based inks to produce high-quality prints that are sure to impress. Our experienced team of professionals can help you choose the best ink for your job, ensuring you get the desired results.